Accelerating Certification and Qualification of 3D Printed Metal Parts Using Machine Learning

| Provided by | Professor Hua Wang in Computer Science |

| Homepage | minds.mines.edu/project/addmfg/ |

| Funding | DOD-OEA, Phase I: 2017/06 – 2018/12 (completed), Phase II: 2019/02 – Present. |

| Job opportunity | You may apply for a summer job to work on this project. |

Project Description

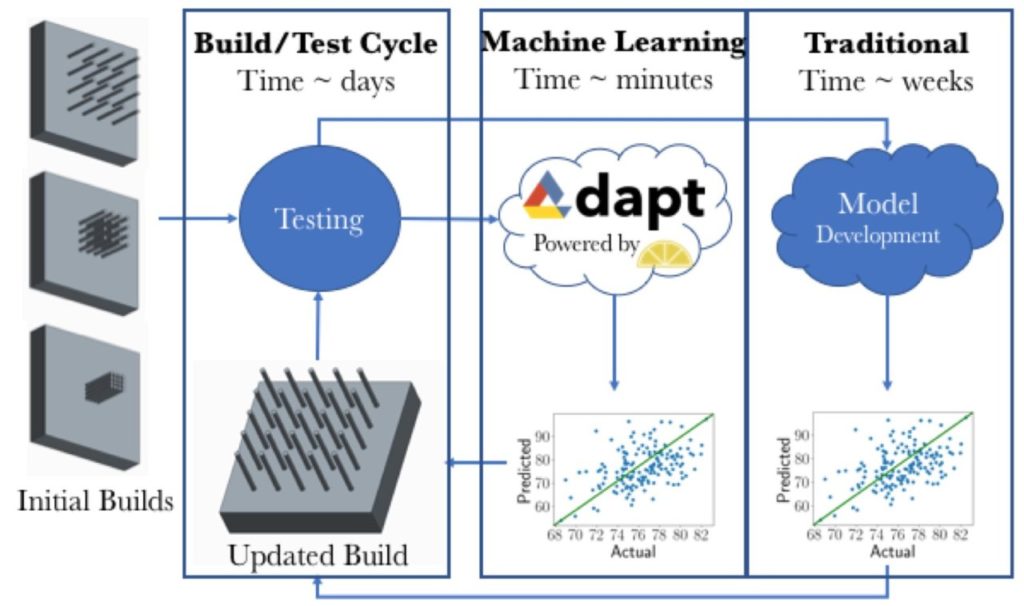

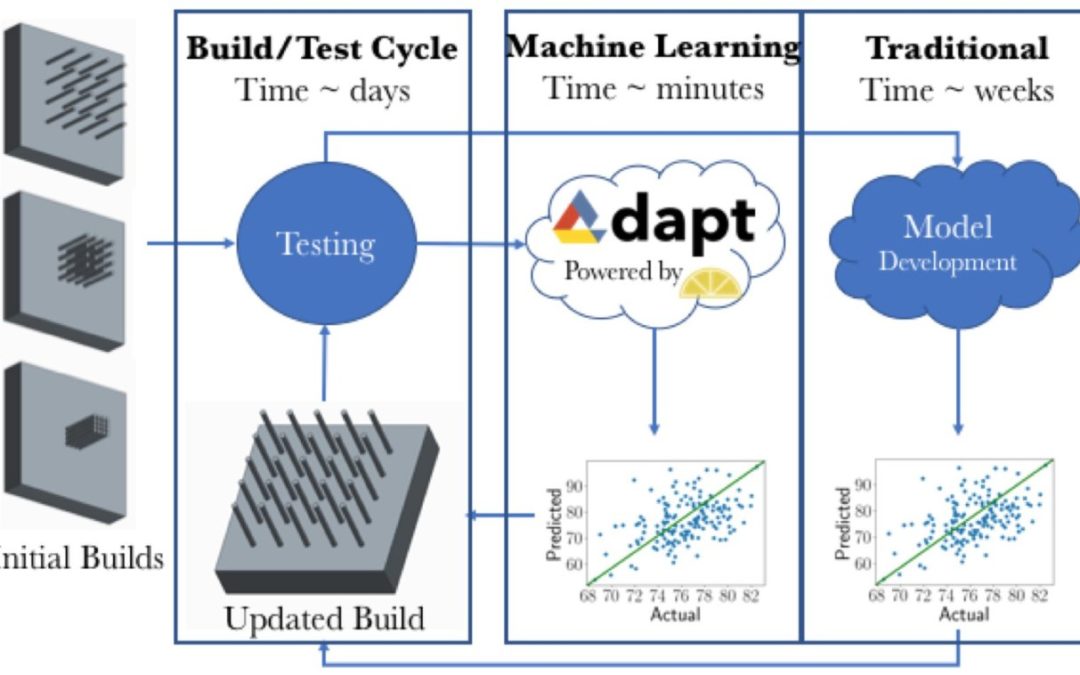

Additive manufacturing (AM) and data-driven design are becoming increasingly common in a wide range of industries. Unlike plastics 3D printing, which can be done by hobbyists in their homes, AM of metals requires a high-level of skill, expertise, and specialized know-how to adjust and tune the manufacturing process for a specific part geometry, material, or desired functional outcome. As such, building a new part or changing to a new material with AM processing is currently time consuming, tedious, and expensive (on the order of 5 years and $5M for a single “A-Basis Allowable” part). Correspondingly, the economic uncertainty of launching innovative products or entering new, untested markets often renders AM cost-prohibitive. As AM has gained popularity in the last decade, this has been the most critical obstacle inhibiting its mass adoption as a production technique rather than as a rapid prototyping method.

Source: MInDS@Mines

Recent Comments