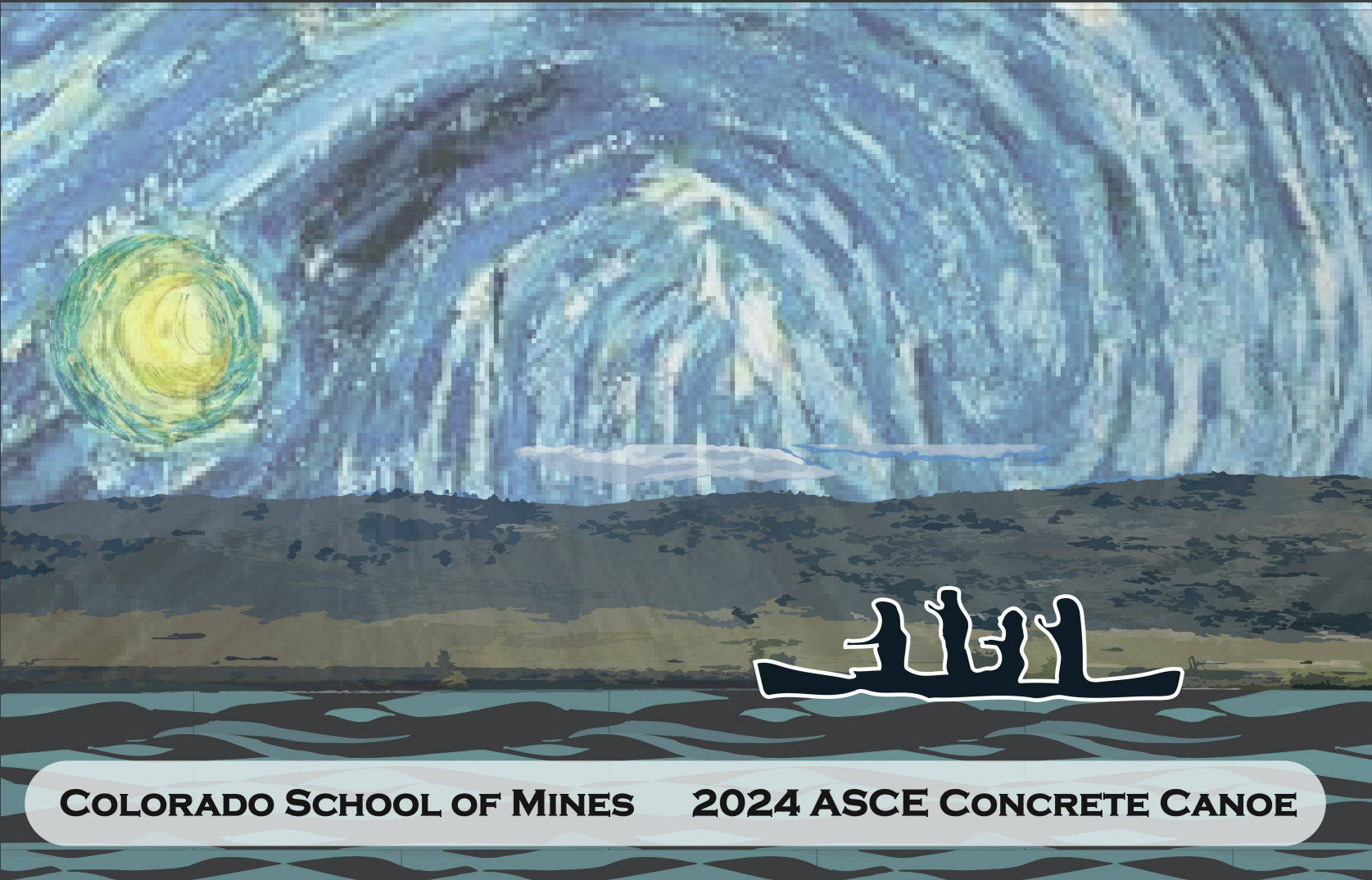

Concrete Canoe 2024

Hello! We are the 2024 Mines ASCE (American Society of Civil Engineers) Concrete Canoe Team. We would love to tell the story of where we are planning to go this year, celebrating 150 years of engineering excellence at the Colorado School of Mines!

Team Members

Inga Almgren, B.S. Civil, CFO Ialmgren@mines.edu

Nick Beckman, B.S. Civil Minor: Economics, Structural Lead Nbeckman@mines.edu

Nathan Commissariat, B.S. Civil, Communications Nathancommissariat@mines.edu

Julie Friedman, B.S. Civil, Mix Design/Theme Jfriedman@mines.edu

Riley Miller, B.S. Civil, Hull Design Rmiller5@mines.edu

Jeremiah Vaille, B.S. Civil Minor: Economics, Mix Design Jdvaille@mines.edu

The main objective of our project is to build a full-scale canoe entirely out of concrete that floats and performs well in races. We plan to accomplish this through collaboration with industry professionals, the Bureau of Reclamation, professors here at Mines, and advisors from past concrete canoe teams.

We will compete in the ASCE Concrete Canoe competition at the regional level, and hopefully earn a spot at the national competition! The events for the competition include submitting an 18-page report on our methods and process, displaying our full-scale canoe, a technical presentation followed by a Q&A session about our design process, and then races where we will compete against other schools for the fastest race times and highlight the durability of our canoe. As a new part of this year’s competition, they have also introduced an infographic where we will explain our design and production processes in a visual format using pictures.

Another exciting change to the rules is that we can use stains! Our theme this year is Van Gogh’s Starry Night, allowing us to take advantage of using colors to make our Canoe look incredible! We plan to use a mixture of stains and pigmented concrete to create a painting to be proud of on our Canoe. To celebrate the 150 years of Mines history, we plan to show a scene of Gugenheim and the M in place of the village that is traditionally seen in the painting. This will allow us to highlight a couple of aspects of Mines beautiful campus at the regional and (hopefully) national level!

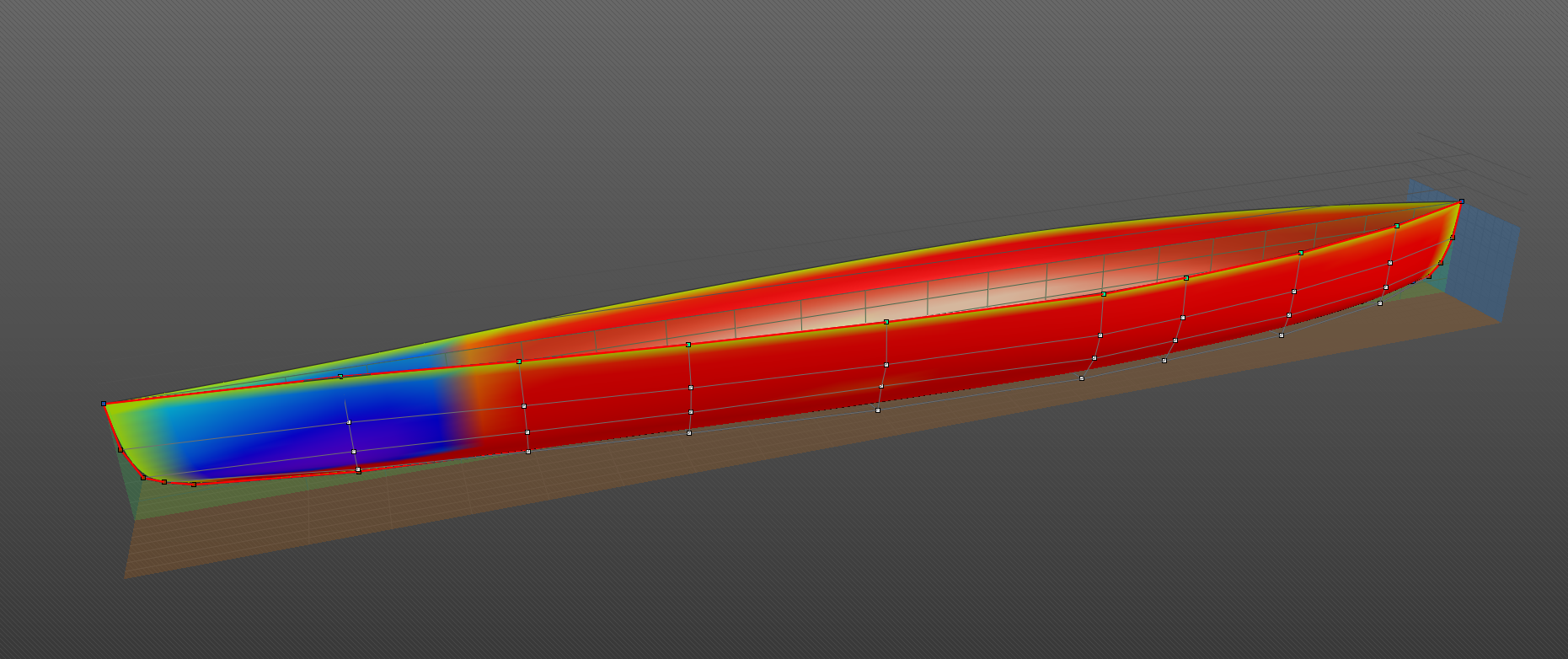

We are extremely excited to be learning so much about lightweight concrete mix design! Before we can race our canoe, we must prove it will float even if it breaks by submerging it in water and then letting it go, a test called the swamp test. We are also excited to learn about hull design! We want our canoe to be fast in the sprint races, but also be able to turn quickly for the slalom races. Our team is studying up on things other teams have done, as well as learning about hydrodynamic designs.

Our team is planning to hold on to the tradition of Mines Engineering excellence, while also innovating and improving on past year’s designs. One of the big innovations we are implementing is using a male mold instead of a female mold, as has been used in the past few years by Mines teams. A male mold (where we build our canoe from the inside out) will give us better access to the outside of the canoe during the curing process, allowing us to do more aesthetic finishes. We will also be able to spread the concrete more consistently, as we will not need to reach down as far for placement and will be able to easily access the placement surface.

Another time-saving innovation we are planning to implement is ordering some larger foam blocks and cutting them with a CNC machine for accuracy. In the past, many teams have used insulation boards. Using a projector, they traced out 100+ cross sections, then cut them out using hand tools and fastened them all together. We hope that by having fewer cross sections, our team will spend less time cutting foam and be able to put that time towards creating a concrete mix design that allows our concrete to be lighter than water! However, this new method will be more expensive, as we are buying foam directly from a manufacturer instead of insulation foam from a store.

In order for us to make these innovations and utilize these new methods, we need your help! Your support will allow us to produce one of the best canoe’s Mines has seen and hopefully make it to nationals to represent our school!

December 2023

What Are We Up To?

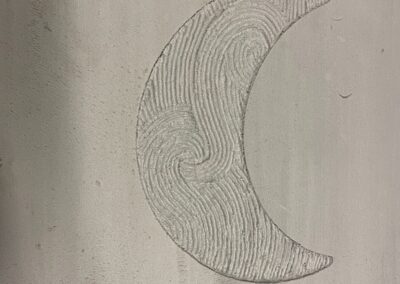

We have been working hard preparing for our pour day this Thursday, December 7th! We fully assembled our mold, and Riley and Nick spent several hours sanding it down to make it look spectacular! They also used a Dremel to cut out some shapes on the mold that will pop up on the inside of our canoe. A big shoutout to Nathan for learning how to use the laser cutter so we could have some clean stencils to use to make beautiful shapes! Jeremiah and Julie put a lot of work into creating and batching several different mix designs, making cylinders that we broke to help decide which mix was the strongest and lightest for use on our canoe! We also cleaned out the trailer, working together to move last year’s canoe and the carry cart out and changing all the wheels on the carry cart. We put solid rubber caster wheels on the carry cart instead of the inflatable ones that were all popped, and hope that they will last us at least until we come back from Regionals! We have loaded up our large trailer and are ready to go to the Bureau of Reclamation on Thursday where we will be pouring our canoe! We plan to use their 100% humidity room to cure our canoe over the winter break. Big thanks to them for allowing us to utilize their space!

How Have We Used our Fundraising Support (so far)?

Recently, support that we received through our Goldmine crowdfunding effort has gone to buying supplies for the pour day, mostly from Home Depot! We needed some new buckets, floats, acrylic (for stencils and inlays), caster wheels (for the carry cart), dowels, foam glue, and several other miscellaneous items! Huge thanks to our supporters for their financial support, allowing us to afford precise and quality tools that will make our pour day a success!

How Are We Overcoming Challenges?

We have encountered a few more challenges since our last update, but we are still looking forward to pouring our canoe this Thursday! It turns out that Cenospheres are not a cementitious material! Even though they are from fly ash, they do not react; this means they will be used as an aggregate in our mix instead of as part of the glue that will hold things together. We also have learned that perlite microspheres absorb a lot of water, which makes our mixes heavier than when we were using some material left over from the team two years ago. We ordered the materials that were used two years ago (Poraver – small glass bubbles) but they will not be here in time for our pour day on December 7th. This means our concrete mix is slightly heavier than water, but we will have enough space to put in some foam bulkheads in the front and back of our canoe that will enable it to pass the swamp test (where we fill our canoe with water, push it down, and then it has to float). We also have a flatter bottom on our canoe this year, so we are using less concrete than last year and may still end up with our desired 250-pound canoe! We will also likely be pouring a second canoe in February with a lighter mix, but having a practice canoe will make that one even more fantastic! (And give us a canoe to practice paddling in:)

Thank you so much for your support! We appreciate your help with our project! Below are a few pictures including, a moon Nick dremeled into our mold, a picture of the last bit of the mold being assembled, and a team picture of us when we loaded the mold into the trailer. Stay tuned for an update in the next week or so on how our pour day went!

For more updates (and pictures!) follow us on Instagram @mines_concrete_canoe!

November 2023

What Are We Up To?

We have been finalizing our mix design (our concrete recipe) and preparing for pour day! All of our materials have finally arrived on campus, so we have been working hard to test different mixes to determine what will work best for our canoe! We have successfully created concrete lighter than water, which is very exciting! Our biggest challenge has been figuring out how to cure hydrated lime. We have also been practicing our troweling skills to prepare for our pour day on December 7th! With our theme of Sterrennacht (Starry Night), we have been practicing using pigmented concrete to paint swirls, a moon, stars, and mountains.

How Have We Used Your Support (so far)?

Your support has also enabled us to order some really cool materials we are planning to use in our canoe! To make our concrete extremely lightweight (think a 250-pound canoe instead of a 350-pound canoe) we are using several lightweight materials. Instead of using cement, we are using a mixture of hydrated lime, slag cement, and cenospheres. These will act as the glue that holds our concrete together. Instead of traditional sand and gravel aggregates, we will use some very lightweight structural fines and perlite microspheres. Because our microspheres are so small, our structural fines work as coarse aggregates in our mix, allowing us to have a good interlocking particle distribution without large gravel pieces. Not having large gravel pieces will allow us to have much thinner layers of concrete for our canoe, and also help our mix to be more lightweight.

Perlite? Isn’t that used in soil?

Yes! Perlite is often used as a soil additive to help prevent compaction and enhance soil drainage. It is the white stuff seen in potting soil mixes and can be added in large quantities to help with succulent planting. However, that is not the only thing it is used for! Perlite is a volcanic glass that is often produced from the hydration of obsidian. It expands greatly when heated and becomes useful in a variety of applications due to its low density. In addition to being a soil additive, it is used as an exfoliant in some cosmetics, in aquatic filtration (pool filters), and in construction and manufacturing. We plan to use it in our concrete as an aggregate. Its low density will help our concrete to be much lighter weight than if we used sand!

For more updates (and pictures!) follow us on Instagram @mines_concrete_canoe!

October 2023

What Are We Up To?

We have been testing concrete cylinders (to determine compressive strength), finalizing our plans for aesthetics, and getting our hull design broken up into chunks that can be cut out of foam using the CNC machine! We have also built a couple of baby boats to test different approaches to laying concrete and practice with mold release. We are working hard to get ready to pour our canoe on December 7, which at the time of writing is just 4 weeks away!

Crowdfunding through the Mines Goldmine!

Support from family, friends, and corporate donors has enabled the team to order all materials required for our canoe, including several lightweight materials. Instead of utilizing the commonly used Portland cement and coarse aggregates, we are using a mixture of hydrated lime, slag cement, and cenospheres, which will act as the glue that holds our concrete together. Instead of traditional sand and gravel aggregates, we will use some very lightweight structural fines and microspheres (small glass bubbles). All in all, a pretty unique mix design. If you are also interested in supporting our team, you can visit the provided link here, until the campaign is scheduled to end November 28th!

Cenospheres, Cenospheres, Cenospheres!!

Cenospheres represent an essential aspect of our team’s innovative mix design! Cenospheres are lightweight spherical particles that are a byproduct of burning coal in power plants. They are very lightweight because they are hollow and filled with inert air. Cenospheres have pozzolanic reactivity, which means they react with the cementitious material’s calcium hydroxide (which is formed when you add water to the cementitious materials). They help make our concrete more lightweight, but also have the added benefit of increasing its strength and making it easier to spread, which will be helpful for canoe construction!

For more updates (and pictures!) follow us on Instagram @mines_concrete_canoe!

The team!

Hull design rendering